Category

Level

Price

Language

Instructors

Rating

5 Courses are found

Intermediate

Intermediate

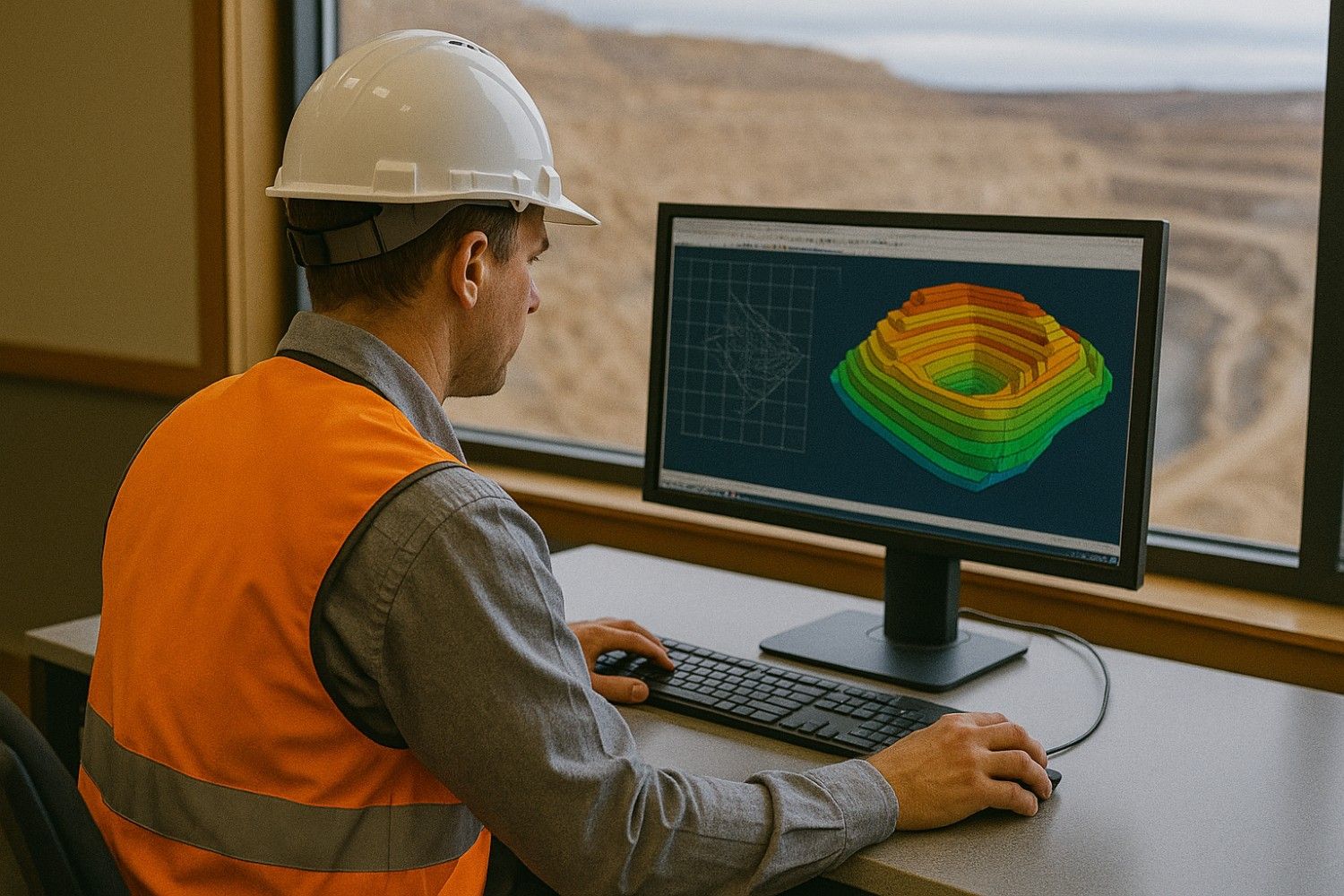

Mastery 2: How to Validate a Block Model for Open Pit Optimization In SURPAC

This work/process will entail ensuring the block model has attributes in their right format e.g. no negative block grade...

-transformed.jpeg) Intermediate

Intermediate

Ore Handling & Transport

Efficient ore handling and transport are critical to the productivity and profitability of mining operations. This cours...

Intermediate

Intermediate

Application of AI and Machine Learning in Mining

Artificial Intelligence (AI) and Machine Learning (ML) are transforming the mining industry by improving efficiency, saf...